ASIA SEWERLINE SDN. BHD.

PIPE LINE REHABILITATION SPECIALIST IN MALAYSIA

PRESSURE PIPELINE REHABILITATION

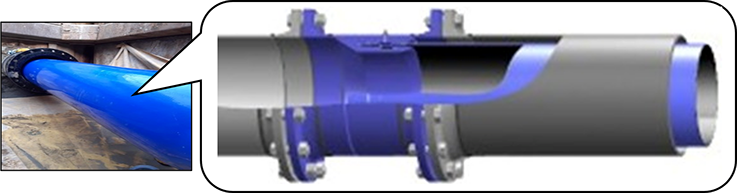

- In order to inflate the liner or to give it its final round shape, sealing balloons are used to close the beginning (pit 1) and end (pit 2) of the liner.

- At an internal pressure of 0.5 bar (approx. 7.3 psi) or higher, the adhesive tapes (maintaining the u-shape) begin to break. All of the tapes will have opened at a maximum internal liner pressure of 1 bar (approx. 14.5 psi).

- One of the sealing balloons features a bypass. Oil-free compressed air has to be blown into the bypass and from there into the liner.

- After inflating the liner, the liner can be cut to a length of 1m (approx.3.3 feet) projecting the host pipe in both the starting and destination pits. The 1m (approx. 3.3 feet) of projecting end of liner is required to install the connectors.

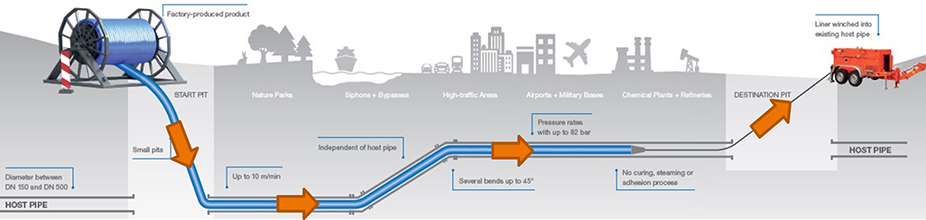

PRESSURE PIPES INSTALLATION

BENEFITS

1. Site preparation and pipe inspection

- Create access pits / use chambers

- Pipe inspection with CCTV

2. Cleaning of the pipeline

- Remove incrustations / protruding welds

- Create free inner diameter

3. Installation of the system

- Insertion and inflation of the liner

- Installation of connectors

ASIA SEWERLINE SDN. BHD.

Suite 19A-22-3A,

Block A, Level 22,

UOA Centre, Business Suites, 19 Jalan Pinang,

50450 Kuala Lumpur,

Malaysia.

©2024 by asiasewerline.

Phone: +603 2161 2688

Email: info@asiasewerline.com